Top Drive is a product by Taglio specifically dedicated to helping marble company in the production of kitchen and bath countertops. With one Click is possible to generate all the information needed to drive all the CN Machine involved in production process.

At the same time it is a fantastic and very fast tool to produce accurate quotation for the end user. The printable documents contain detailed information on cost elements, measures of the work pieces, 3D rendering also using true slabs.

If used together with the other software of the Taglio Marble Suite, Top Drive permits to reach very high levels of integration and productive environment.

Pietra

Automatic and integrated production of kitchen and bath countertops

The supported Operative Systems are:

- Windows 10

- Windows 8

- Windows 7 (Last Version available: Ver. 35.5)

- Windows XP S.P.3 (Last Version available: Ver. 32.3)

languages: italian, french, english

compatibility with: german, spanish, portuguese, russian, polish, romanian ,vietnamese, chinese, cech, dutch.

For info about Hardware configuration write to support@taglio.it

Design

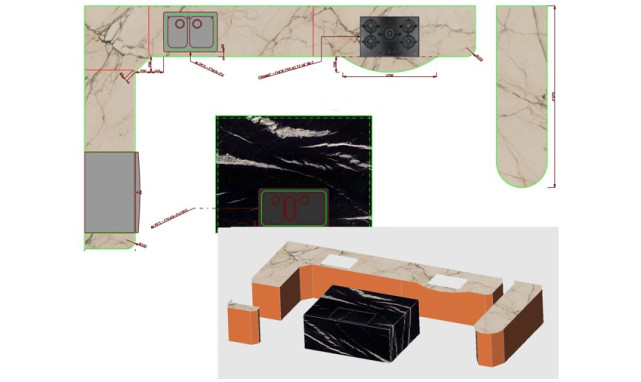

Top Drive provide the geometric “configuration” of the kitchen and bath countertops in a fast and automatic way.

Each new “Project” starts from the layout definition of the countertop. In few simple steps it adds all the components and attributes to reach the completion of the Design.

Very complex projects can be done within minutes.

At the end of the Project, it’s all ready for the following phase without any more managements.

Make offer

The first step, sure the most urgent, is the generation of the estimate of costs. This must be detailed and accurate.

The calculation of the offer is immediate. It use a flexible and customizable price list, which can manage all the cost elements.

Top Drive produces complete reports and printable documents with layout and 3D rendering.

The special module “Lastra” permits a very accurate 3D rendering, using the true images repository from the company slabs store.

Production

With one “Single Click” the project can proceed to the production environment.

After the design phase the project include all the production attributes. According the workshop layout of the company, the project’s machining is split for each machine involved. Top Drive produce the CN files for bridge saws, polishing work center, waterjet, combi machines and edge polishers.

Features

Design Phase

Workpieces Layout Definition

- Free built-in CAD creation

- Import from shapes library

- Predefined macro shapes library

- Import from DXF, DWG, PDF, PLT, PNT files

- Full management of digital template measure system

Edges Geometry Modifications

- Trim, fillet, notches

- Automatic CN corners

- Bumpouts or breakfronts

- Straight, miter or free seams or joint

BackSplash

- Automatic generation of the workpiece to be clued

- Rear / front backsplash

- V cut edges, alloy peg cut

- Polished edges

Sink, Cooker, appliances holes

- Predefined shapes

- Standard custom library shapes,

eventually split for sink / cooker producer - Macro library

Edge Profile

- Hob cutout

- Polished edges

- Drill holes

- Free shape holes

- Grooves

Offer Phase

- Automatic offer generation

- Complete customize price list

- Printable report

- Real material simulation

- Veins matching

- 3D render

Production Phase

- Automatic “One Click” production batch creation

- Preparing workpieces for: saw bridge machines, polishing workcenters, water jet, milling / water jet combo machines, edge polisher

- Processor and post processor library for ALL CN machines