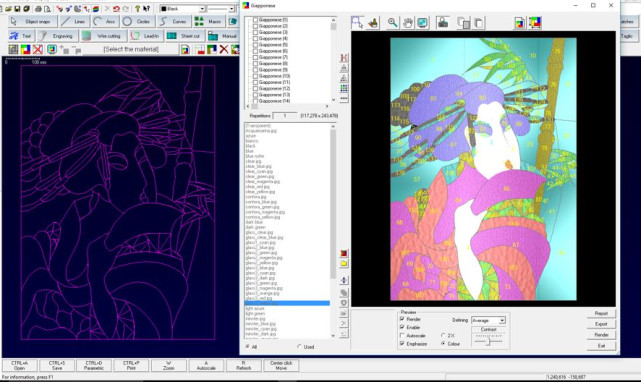

The inlay management concludes by saving the entire parts listed in single DXF / DWG files to be processed on the CNC machine. Alternatively, these files can be imported to third-party CAM systems.

More simply, when the user can use a Taglio CAM (eg. Lastra, Magic Tool), it is possible to create the work production order, from which we get the cutting plans for the machine directly, from Intarsio.

Each work order contains the list of pieces divided by technology, material and thickness. The user, before generating the cutting plans, combines the slabs of the materials they wish to use, specifying the size and quantity.

The Taglio CAM is therefore able to automatically distinguish the pieces to be cut with the most appropriate technologies by associating, for example, the shapes to the water jet machines, the rectangular pieces to bridge cutters and recognizing any UNI tiles that are not required in the production.

Different types of nesting are combined according to the available cutting technology.