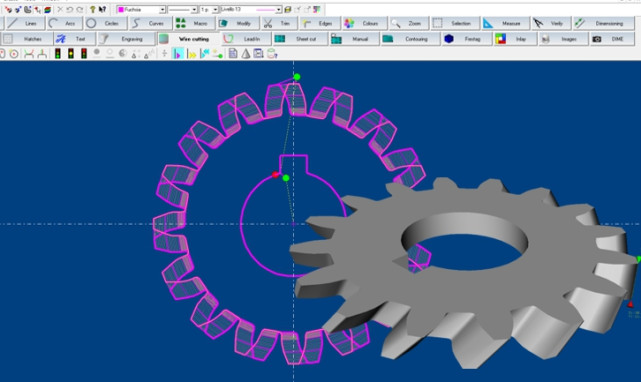

The 2 or 4 synchronized axes are useful for cylindrical or constant conical machining, while the 4 or more independent axes contouring allow variable conical machining in which profiles on the two planes of interpolation (typically XY and UV) have different shapes.

Values of slowing down can be assigned automatically or manually as well as linear unloading, circular unloading, pause on edge, work regimes and synchronization points. The start and stop points on the profile are independent from the two planes of interpolation.

Erotag is part of the CAD Logotag that allows users to generate in a simple and quick way the machining profiles without using third-party drawing programs. It is possible to import DXF, DWG, EPS, PLT, and DSTV files as well.