TAGLIO VERSION 34: The new version of Taglio CAD CAM software

NEW LICENSE MANAGEMENT WITH ONLINE ACTIVATION, IS NO LONGER NECESSARY

RECEIVE THE CODES BY EMAIL OR FAX

Taglio software backup management for easier settings recovery

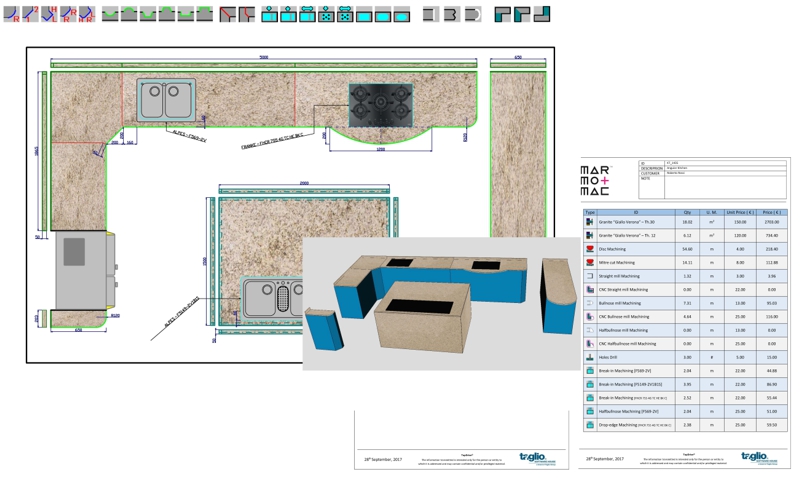

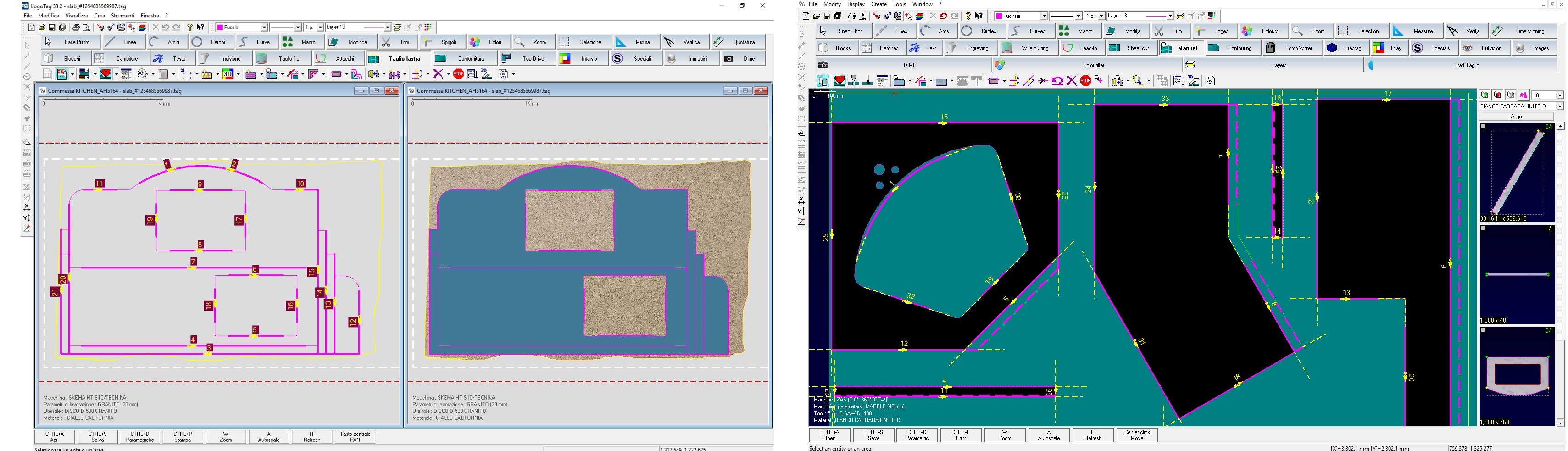

THE CAD FOR COUNTERTOP FABRICATORS

- New window for photorealistic layout generation with improved 3D and automatic vein-matching / open-book functionality

- It is possible to program the sink top directly in Touch Drive and Top Drive / Slab. Part of the Frestag processes are now integrated and available in Logotag

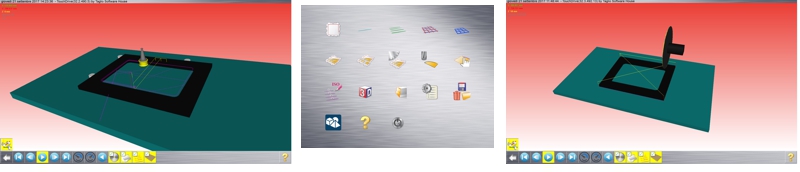

THE CAM FOR TOUCH-SCREEN OPERATOR PANEL THAT SIMPLIFIES THE USE OF BRIDGE SAWS AND WATER JET MACHINE

- New button to display the measures of the drawings / parts

- Dedicated key to create rectangular shapes without having to use Parameters Figures

- Automatic conversion of the default white color in many DXF/DWG to purple (main color)

SAW BRIDGE

- Complete management of manipulators and suction cups

- Increased operation on machines with reduced rotary axis travel

- Full Function Emulation Numerical Control

- Management of auxiliary systems such as Laser Projectors, Video Projectors.

- New command to machine completely with the disc: L-shaped cuts of the pieces (function already present in Lastra)

- Optimisation of cuts and pick-up to reduce lifter moving time

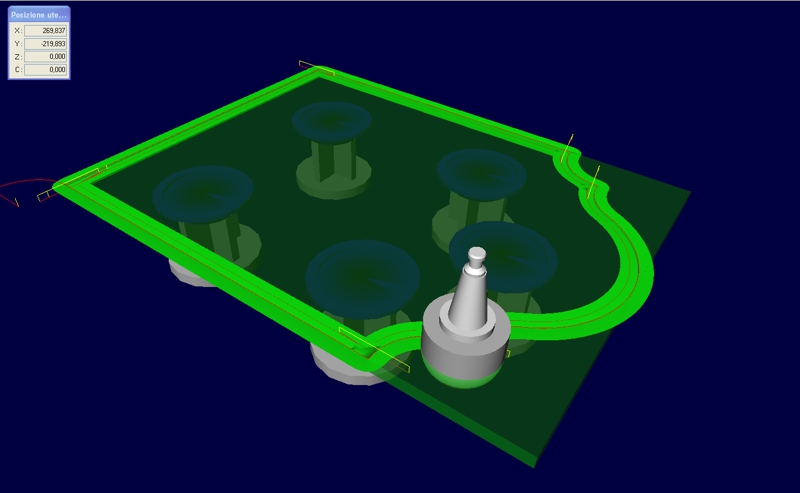

MILLING CENTER

- Machining for Countertops:

Edge Contouring and Polishing

Drilling

Suction cups - Full Function Emulation Numerical Control

- Management of auxiliary systems such as Laser Projectors, Video Projectors.

- Tool radius compensation from Cam or CNC (already present in Frestag)

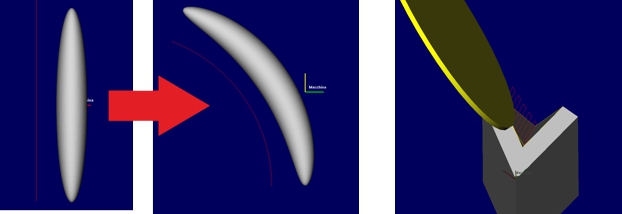

WATERJET\PANTOGRAPH

- Inclined cuts for Drop Edge

- Inclined cuts for internal Drop Edge

- Full Emulation of Numerical Control Function

- Management of auxiliary systems such as Laser Projectors, Video Projectors

- Nuovo comando per l’esecuzione di tagli a 5 assi (Bevel)

- New command for 5-axis cutting (Bevel)

COMPLETE MANAGEMENT OF WATERJET MACHINES AND PRODUCTION CYCLES

New automatic positioning strategies of lead ins

THE CAM FOR GLASS MILLING

- Parametric Cad Cam: allows you to modify the dimensions of the starting drawing of a project already worked on.

- Technological Macro Holes and Notches: starting from a library of standard machinings, it allows to position them on a starting profile.

- CAMDxf Cutting: by using suitably structured DXF drawing files, it allows to generate the machining ISO files in a totally automatic way.

- CAMDxf A+W support

- Vertical Machines Management for continuous production

THE 2D CAD: DEVELOPED TO MEET ALL THE NEEDS OF THE CNC MACHINES

- Module for selecting and importing surfaces from 3D Iges and Step files

- Import of cutting profiles from 3D Iges and Step curves.

- CAMDxf" mode for direct generation from DXF files to ISO files

- Control with related reports when importing dxf/dwg files in inches and/or mm. The actual measurement set in dxf/dwg is notified

- Dxf/dwg containing white entities are converted to purple when imported into Logotag and Touchdrive

THE CAM FOR 3-AXIS STONEWORKING CENTRES AND/OR LATHES

It is now possible to maintain the positioning of the pods when loading the new drawing/profile to be machined, in order to reduce both the programming time of the piece and the execution time on the machine. In this way, the positioning cycles of the pods (where expected) can be avoided.

THE CAD LOGOTAG OPTION DESIGNED TO SIMPLIFY THE READING AND MANAGEMENT OF COMPLEX DRAWINGS SUCH AS INLAYS AND FLOORS

Exporting the inlay to Top Drive

IL CAD/CAM FOR 5 AXIS WATERJET MACHINES

- Improved automatic functions: new 5-axis bevel specifically for marble and glassmakers. (You can continue to use the normal bevel function to cut the sheet metal.)

- Marking management whith white color (as in Magic Tool)

THE SOFTWARE FOR THE MANAGEMENT OF SLAB CUTTING MACHINES

- Top Drive Project : Creation of Countertops for Kitchens and Bathrooms up to the preparation of quotes

- Top Drive Production : Automatic "One click" passage to the generation of the machining operations of Cutting Sheets / Wj / Machining Centres.

- Vein Matching

- New 3D rendering engine: Possibility to work on multiple Z levels

- Automatic completion function of adjacent placement schemes

- Open Book

- Ambience through the creation of walls and floor

- Tool radius compensation from Cam or CNC (already present in Frestag)

THE 3D CAD / CAM FOR STONE WORKING CENTRES WITH UP TO 6-AXES

- Possibility to apply cuts on solid faces

- Solids folding function

- Striped surface: creation of surfaces between two flat profiles

- Radial machining (shower tray): radial machining between two profiles