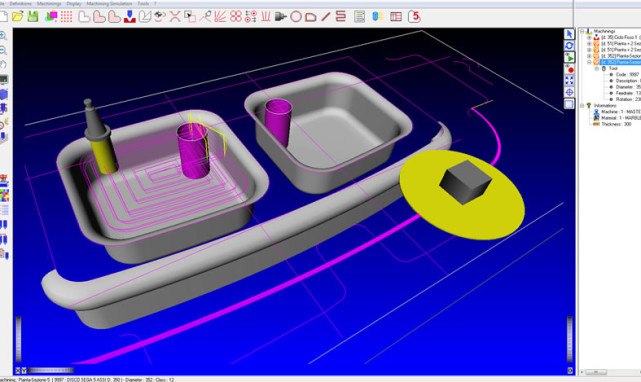

Frestag is the CAM suitable for 3-axes stone-working centres and more in general for the stone industry. The non-interpolated lathe machining is supported as well.

Focusing on the user-friendly aspect, it does not need particular IT skills and can been used from all the operators indistinctly. The user interface (UI) acts as a wizard, leading the user during the processing steps and reducing the probability of making errors during the programming phase.