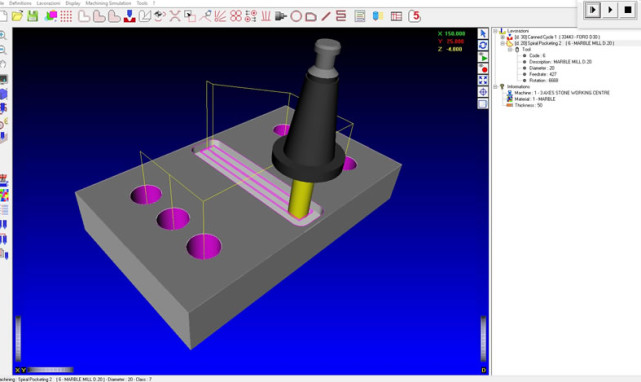

Focusing on the user-friendly aspect, it does not need particular IT skills and can be used by all the operators indistinctly. The user interface (UI) acts as a wizard, leads the user during the machining steps and reduces the probability to make errors during the programming phase.

Metallo

The CAM suitable for the 3-axes working centres and more in general for the metal industry.

The supported Operative Systems are:

- Windows 10

- Windows 8

- Windows 7 (Last Version available: Ver. 35.5)

- Windows XP S.P.3 (Last Version available: Ver. 32.3)

languages: italian, french, english

compatibility with: german, spanish, portuguese, russian, polish, romanian ,vietnamese, chinese, cech, dutch.

For info about Hardware configuration write to support@taglio.it