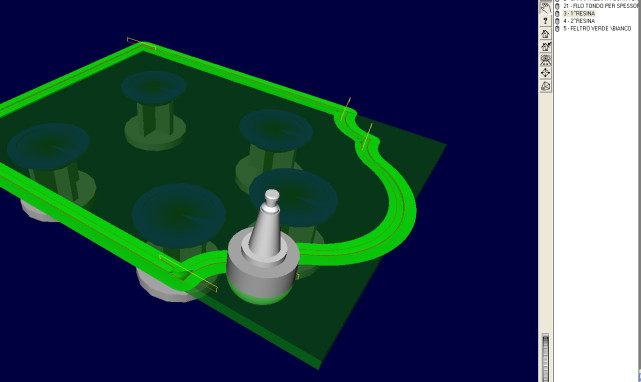

GlassCam is a program for machining the glass for work centers controlled by numeric controls.

Designed to handle all types of tooling, grinders, rotary, is the first product of a new generation of “experts” to help operators with automatic choices based on the experience of work already carried out. Easy to use and learn, friendly interface guides the operator through the various phases of processing without the possibility of making mistakes. There is no limit to the complexity of the profiles or the number of elements to be considered in manufacturing. Automatically detects any collision zones cross-cutting of multiple profiles.

All cycles are executed independently of the characteristics of the numerical control and the geometry of the machine.

In line with the technological characteristics of machine tools available, GlassCam and the Post Processor will drive them properly: edge, beveling machine, engraving, drilling machines with five or more axes, with all types of tool change, change of head, lubrication, dressing tools, etc. ..